-

FRNC-5PC is a rating program for general purpose fired heaters. Based on user-supplied heater geometry, combustion data, and process information, the program calculates operating parameters such as firing rate, heater efficiency, tube skin temperatures and required tube thicknesses, gas-side temperatures and draft, process temperatures, pressure drop and flow regimes, heat duties and fluxes, and much more.

FRNC-5PC simulates entire radiant sections of most heater types, coil configurations, tube and fin types, ducting, stacks, and external transfer lines. FRNC-5PC can simulate the heat recovery sections of all types of furnaces, boilers and turbines.

FRNC-5PC has a user-friendly graphical input system and multiple, user-controlled output options, such as heater data sheets, graphical output, spreadsheet output and tabular output. The input system contains on-line help and input limit and error checking.

-

Following are some of the many uses of FRNC-5PC:

- Reduce Heater Operating Costs

- Lower heater fuel consumption

- Evaluate air leakage, air preheaters and heat recovery coils

- Increase Heater Capacity

- Identify thermal, hydraulic and draft limits

- Model process controls

- Minimize excess air for NOx control

- Evaluate Process Changes

- Stream rates, temperatures and compositions

- Steam injection

- Process stream flow regimes and vaporization

- HAZOPS and Process Safety Management reviews

- Check New Heater Designs

- Optimize capital expenditures

- Determine firebox and overall heater efficiencies

- Evaluate most boiler types

- Minimize Unplanned Shutdowns

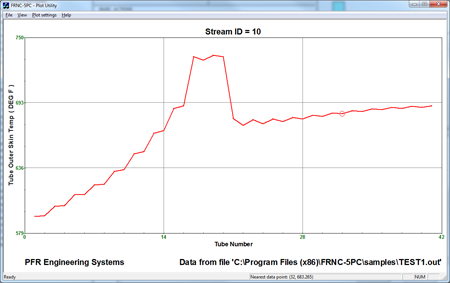

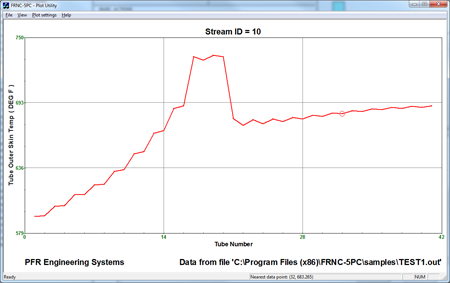

- Provide detailed tube skin temperature and tubewall thickness profiles

- Evaluate fouling and coking effects

- Train engineers to troubleshoot heaters

-

User Interface

Firebox Data

Coil Section Data

Steam/Water Injection

Hydrocarbon Mixture

Firing Conditions

Schematics

-

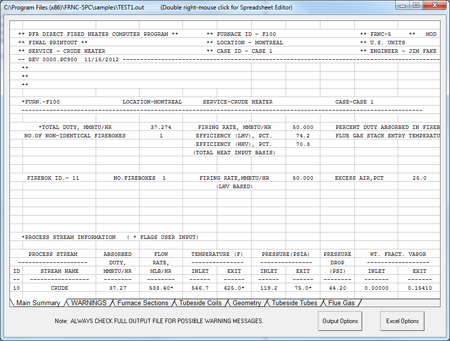

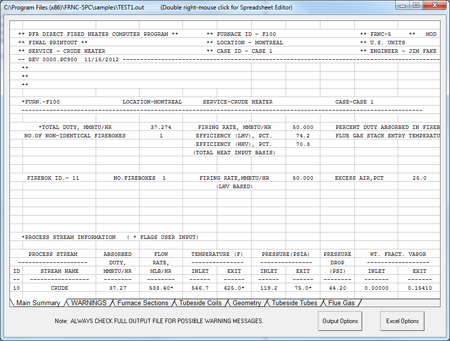

Output Spreadsheets

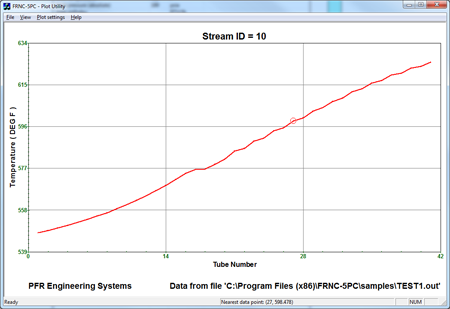

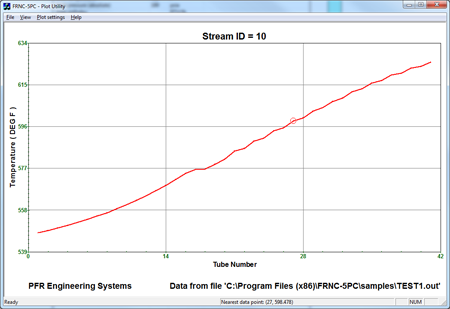

Plots

Plots

-

-

FRNC-5PC

FRNC-5PC